It appears that your cart is currently empty

PLASTEC Ventilation introduces its new fan curves

When it comes to choosing a fan for your buildings, laboratories, fume hoods, cabinets or scrubbers, you will need to understand fan curves sooner or later.

You can download our latest fan curves here: Download Specsheets

What's new about PLASTEC fan curves ?

New design

Reminder: Each fan is defined by a non linear curve of the Static Pressure Ps in function of the Flow Rate Q at a given speed rotation N.

- On PLASTEC graphs, by convention the red curve represents one fan model at a given power and speed. This is the fan performance without frequency variation, i.e. at maximum speed (60Hz)

- The blue doted curve represents the same fan performance but at lower speed rotation.

Energy saving alternative models

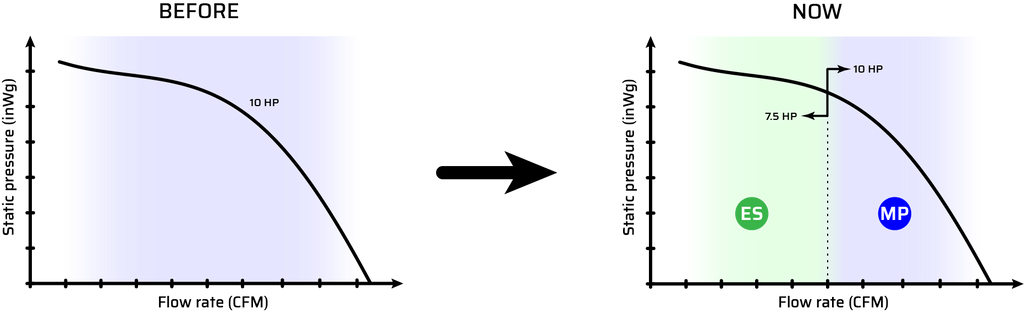

If you take a look at a few models like the PLASTEC 25 or 35, you may notice that some curves are split in two parts. The idea here is to offer two different powers on the same curve:

- A smaller power for lower CFM. This model is called "ES" for Energy savings

- A higher power for higher CFM. This model is called "MP" for Maximum power

This new system allows our customers to find the best fit for their fan installations while saving energy at a lower price.

New data tested and approved by AMCA International

These brand new curves are approved by AMCA International since the beginning 2021. All PLASTEC Ventilation fans have been tested according to AMCA 211 and 311 for Sound and Air at the AMCA partner laboratory "CETIAT". You can download the three AMCA catalogues here.

0 comments