Proper exhaust fan sizing represents only the initial step in effective ventilation design. This article examines the critical importance of exhaust plume height and the potential consequences of inadequate plume dispersion, including re-entrainment of hazardous fumes into building systems.

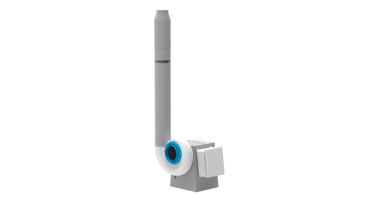

Most engineers and facility managers assume that if an exhaust fan is sized correctly, the problem is solved. But here’s the hard truth: if your exhaust plume doesn’t rise high enough above the roofline, you could be sending hazardous, corrosive, or odorous fumes right back into your building. That means: Risk of re-entrainment into air intakes Accelerated corrosion of building structure Potential code compliance issues with local authorities Increased liability for both designers and owners The question is simple: how...